Precision Horology

Q1 MOVEMENT

The movement design is quite straightforward and is time only with a regulator style

dial. The hours appear in an aperture in the dial. The dial itself is a solid piece

of etched silver with the numerals filled with enamel. The hands are impulsed once

a second by means of a solenoid arrangement acting on a ‘scape wheel and activated

by one of the mercury relays as the pendulum passes the center point of its excursion.

The solenoid draws less than .1 amp and is an insignificant load on the relay, well

within the operating specs. The movement has been running for almost 7 years now

with no problems whatsoever. I used C-

When I built Q1, my shop wasn’t particularly well equipped and the project was somewhat ambitious. I had only a Myford Lathe and a small Clausing Mill as well as the usual hand tools. Because of that, a number of the machining processes were quite challenging. Because I enjoyed designing and building this clock, I decided to enhance my workshop as time and finances permitted. My workshop today is fairly well equipped and sheer enjoyment to work in.

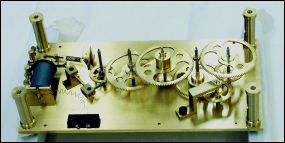

(LEFT) Rear view of the dial movement. All of the bearings are miniature ball bearings to mitigate wear.

(BELOW CENTER) The seconds impulsing mechanism. C-

(BELOW RIGHT) An open view of the dial movement. I opted to relieve the gears in an untraditional way. It’s a bit faster and I think a little unusual and attractive.

The regulator dial has an aperture through which the hours are viewed.

The dial is

made of solid silver. To the right is a u-

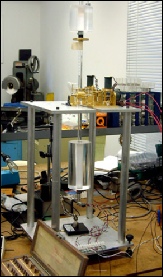

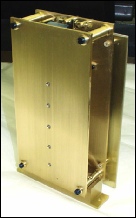

Two views of the finished movement on its test stand↨

The bell jar cover was custom made for the clock. At the right rear is a vacuum vernier gauge. It contains a capillary tube resting in a tinted vacuum oil that rises in the tube

The unfinished movement during the trial and testing phase.↓