Precision Horology

Q1 PENDULUM

There were a number of materials I could use for the pendulum design but I decided to eliminate everything from consideration except INVAR and fused quartz. Up until the late 19th Century, many materials were used as pendulum rods in precision clocks including steel and wood.

Because the coefficient of expansion (COE) of most of the materials used was significant,

various schemes were used to compensate for the change in the length of the pendulum

rod in an effort to maintain the same effective length in order not to affect the

timekeeping of the regulator. Although almost all of the devices used to compensate

were effective to some degree, they all had problems of one kind or another which

made them imperfect. In the late 19th Century (1897) Charles Edouard Guillaume, the

Director of the International Bureau of Weights and Measures in Sevres, France, created

a material that appeared to have almost no COE. It was an iron-

Manufacturers of precision pendulum regulators quickly adapted the material for use as pendulum rods in their precision timepieces. Riefler was one of the earlier users of the material and had great success with it in their precision regulator clocks. Riefler realized early on however, that although INVAR had a very low COE, the material was somewhat unstable. They spent a great deal of time stabilizing every batch of invar they received by alternately heating and cooling the invar over a period of weeks in large ovens after which each piece to be used as a pendulum rod was calibrated before use and individually compensated in the very clock it was used in. Almost all of the makers of precision timepieces adapted the use of INVAR in their clocks including Leroy, Shortt, Strasser and others. It became the material of choice for use as a pendulum rod. In the mid 1950’s Fedchenko used it for his high precision timepieces. I’ve had the opportunity to have had 5 of the Fedchenko clocks in my possession at one time or another for repair and noticed that even in these clocks, some had positive compensation applied to the INVAR rod and some had negative compensation. Only one of these clocks had the correct compensation by the time I had them because of the unstable nature of the INVAR.

I’ve seen Satori pendulums on a number of regulators including a particularly nice

wall regulator by Dent, although it clearly was not widely used. Riefler experimented

with fused quartz also but decided against it because of the problems inherent in

the machining process. To avoid the problems of INVAR, I decided to use a fused quartz

pendulum rod. Where INVAR has a nominal COE of 1.6 x 10-

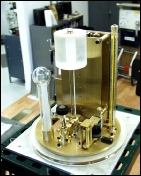

My initial thoughts were to use a knife edge suspension to support the pendulum assembly. In order to minimize the effects of knife edge wear, I decided to make a compound pendulum of the Schuler type. For an ordinary pendulum, wear on the surfaces of the supporting knife edge as small as 4 thousands of an inch would vary the rate of the clock by as much as 4.3 seconds a day. The Schuler pendulum minimizes the effect of this type of knife edge wear by several orders of magnitude. The effect of the same amount of wear on a Schuler type pendulum would result in a loss of only about .0002 seconds a day. The Schuler compound pendulum is constructed so the center of oscillation of the whole pendulum is actually at the point of suspension. I used fused quartz for the pendulum rod and I also used fused quartz pendulum bobs to minimize temperature effects

The lower quartz bob machined with a 14mm thru hole

The top quartz bob is somewhat small than the lower bob shown here mounted in the test stand

An experiment with an Invar pendulum bob mounted at the top of the pendulum rod.

The stabilizer for the parallel quartz rod that hold the hall sensors. It has the same COE as the rod and stabilizes the position of the sensors.

The lower bob mounted on the rod. Note the small magnet mounted on the rod and the hall sensors on a quartz rod

The pendulum rod mounted in the clock showing the original cross spring suspension which was changed to knife edges.

The use of fused quartz for pendulum rods was pioneered by Karl Satori in Vienna. He patented a pendulum with a fused quartz rod in 1912 that claimed variations of only 40 to 50 milliseconds a day when used with a rather ordinary Graham deadbeat escapement wall regulator.