Precision Horology

Q2 SUSPENSION

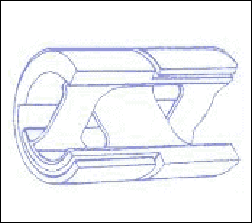

Flex bearings are constructed utilizing flat springs which are locked and crossed

at a 90 degree angle and encapsulated in a cylindrical steel housing. A cutaway on

the left shows the construction of the C-

When I had originally designed Q2, I made the decision to use a knife edge suspension. The pendulum in Q2 is a true compound pendulum and I wasn't at all sure that a knife edge suspension would be appropriate for this type of pendulum.

As it turned out -

the knife edge in a gimbal assembly as is done with standard pendulums to keep them

vertical. A gimbal assembly is not practical for a compound pendulum because of the

instability it creates (I saw this in an experimental compound pendulum I built to

try the concept). At this point I disassembled the pendulum and fitted it with C-

The original Q2 knife edge suspension

The new Q2 cross spring suspension known as a C-